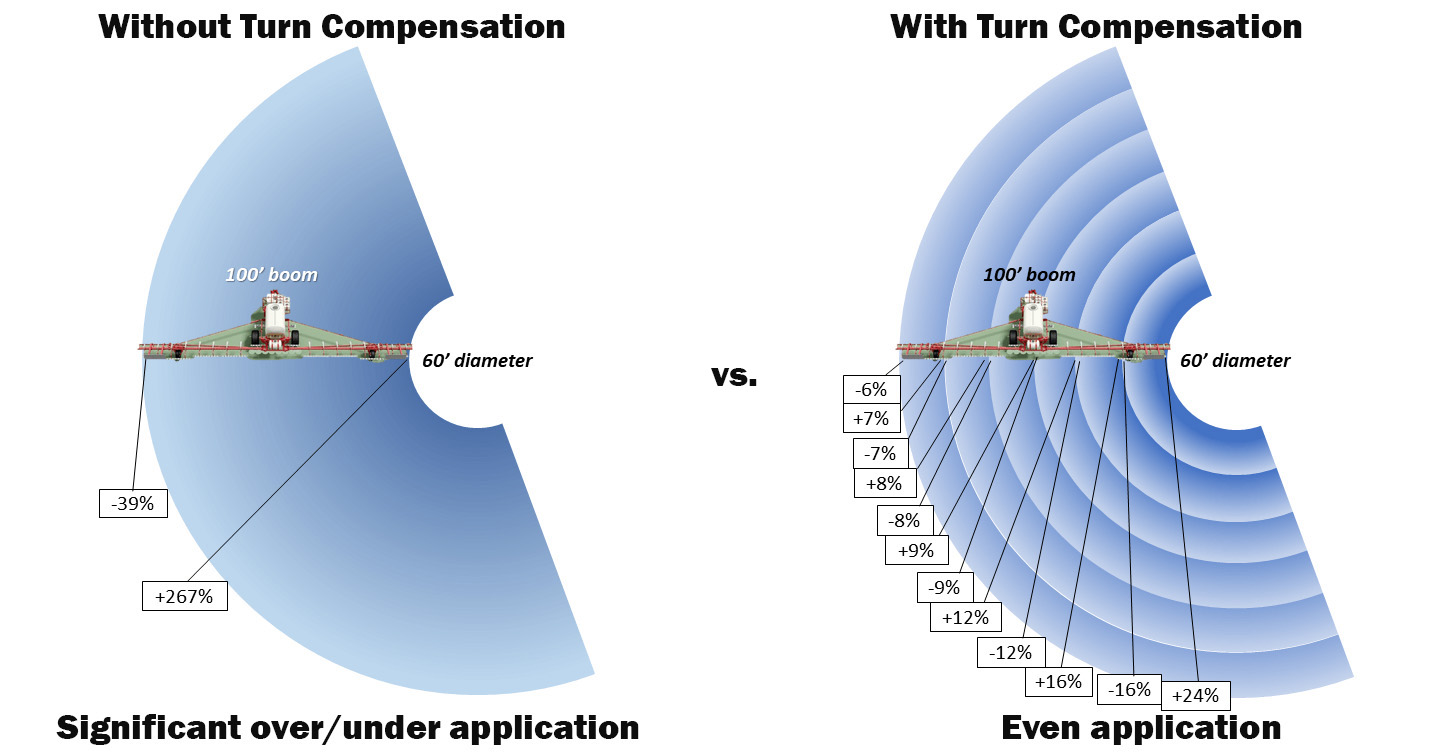

Today we have good news if your Sprayer is equipped with Aim Command spray system. We have an affordable upgrade to add Turn Compensation by section to your current machine. This system can be added to standard spray systems as well. This upgrade does not apply to sprayers with Aim Command Pro and Aim Command Flex as they already have Turn compensation. The Capstan EVO Upgrade offers you the well-known consistency in performance of pulsing nozzle technology, takes care of over and under-application within turns through sectional turn compensation. Its intuitive in-cab interface offers you real-time system feedback and diagnostics per module.

On an uncompensated boom the outermost nozzle is underdosing 39% and the innermost nozzle overdosing by 267%. Repeated year after year this will lead to avoidable weed problems. Young’s Equipment has the right products to take care of this problem for you, as well as the qualified technicians to install them for you. Take advantage of affordable products and no-hassle installation, our Product Specialists will be happy to answer all your questions and quote a solution tailored to your needs.

With the harsh temperatures winter in Saskatchewan throws at us, we thought now would be the perfect time to share some cold weather operating tips for your equipment. No matter which Young’s Equipment location you live closest to, you’re blessed with cold and snowy weather that is hard on your machines. The following five tips will help keep your machines running at top performance when the mercury retreats into that little bulb at the bottom of the thermometer.

In case you have further questions about winter operation, the Winter Inspections program or Hy-Tran SSL, the Parts and Service staff in all our locations will be happy to answer them for you. We are looking forward to hearing from you soon!

Accidents can happen faster than you think, one small mishap and your MacDon header might look like the one above. If this happens to your equipment, Young's is here to help. We have the expertise, the tools and the unique specialty equipment to straighten and repair your header.

This offer is available for your operation, no matter what colour equipment you run as well as insurance companies throughout the province. Don't hesitate, give your local Young's Equipment Service Department a call or have your insurance adjuster call us.

Young's Equipment, Saskatchewan's top MacDon dealer, is here to help.

When the conversation comes to Grain Bags, top of the line quality means something different to everybody. Some folks value a grain bag made out of multiple layers, some value unprecedented grain bag thickness. That’s why we decided to offer you three different top brands in various sizes instead of limiting our product range to just one brand like our competitors do:

High performance Grain Bag solution that offers you the industry's first 7 layer SmartStructure technology for greater tear and puncture strength and more resistance to "slumping". Available in lengths between 200 and 400 feet.

Tough and durable Grain Bag that provides 9.3 mil thickness. Available in lengths between 250 and 500 feet.

Unprecedented 9.5 mil thickness ensures ultimate durability in the most extreme conditions. Available in lengths between 150 and 300 feet. Manufactured by HITEC.

Let us know if you have any questions about Grain Bags, our Parts Professionals in any of our locations will be happy to answer them for you and find the best solution for your specific needs. And please keep in mind, quantities are limited!

We have the Professionals and the parts to make sure your Header runs at peak performance this season. We would love to help you harvest more of what you grow, and do it quicker. Our Header Inspection Program is the ideal opportunity to be ready for Go-Time and ensure your Header gives you the top results you expect.

And why not get it done for the best price of the year during our 2019 Header Inspection Program? Here's are the Inspection prices we're happy to offer you:

Call or come in to any of our nine locations to learn more about our Header Inspection Program, our Service Managers and Service Advisors will be happy to answer all your questions. And while you're at it, ask us about

Two essential products that are designed to optimize your Header's performance. We're looking forward to seeing you soon.

The Never Spill Spout in action: You can fill trucks and bins without needing to climb ladders to constantly check how full it is! The Never Spill Spout sounds an alarm when your bin is full, preventing spillage! Never offerfill a bin again! Never plug another auger! No need for individual bin indicators! Never spill another bushel!

Stay in the truck, move up as the alarm sounds, and fill your truck front to back by yourself with ease.

New Model "NO Snag Spout" NOW AVAILABLE! The spout is bright orange to increase visibility at night! Also now the Never Spill Spout includes 2 alarms for even more volume!